Zfx Inhouse 5x - Control manual

Malfunction oil pump

Malfunction oil pump

1) If a wet processing program is running and the oil pump is not working, the program must be aborted immediately. Otherwise it can lead to damages.The first step is to check the pressure on the manometer on top of the big blue container of the coolant filer.

If the pressure is higher than ~50kPa, contact the Zfx Service & Support Team.

2) The next step is to check the oil level in the oil can.

If there is not enough oil in the can, please check if the blue swarf filter inside the workspace is blocked so the oil can not flow off. If this happened the swarf filter has to be cleaned/changed.

If this wasn't the reason but the oil level is under the red line from the picture below, you have to order a new cutting oil.

In the meantime it is not possible to mill wet processing programs. Therefore from time to time you have to have a look at the oil level.

Insert the closure of the b-axis, otherwise all the oil will run in to the suction.

Now it is necessary to listen if the oil pump is working and how fast it is pumping. To hear the pump better, open the front door, where the pump is located.

4) Check the pressure on the manometer also while the oil pump is running.

The pressure should be ~40kPa.

If the pump is working but the pressure is not increasing, the coolant filter has to be cleaned/exchanged. For the PDF download of the instruction click on "Coolant filter".

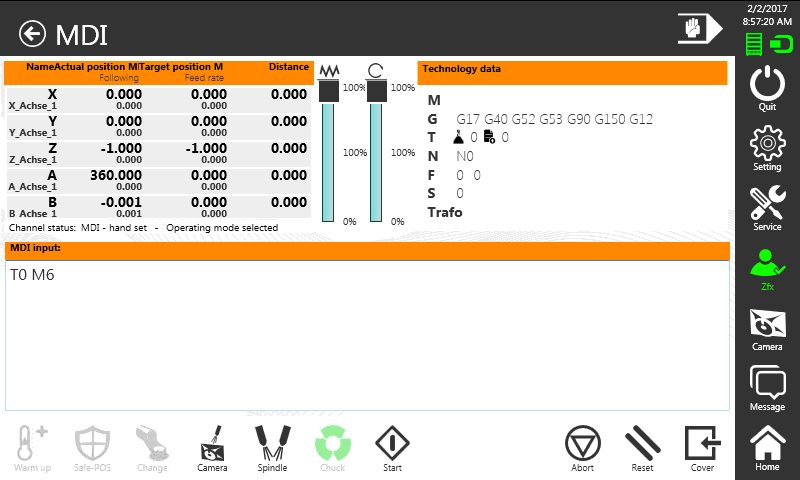

5) Make a tool call in "MDI"-Mode and check again the manometer to see if the pressure is increasing during the measuring.

The Pressure should not change during the measuring.

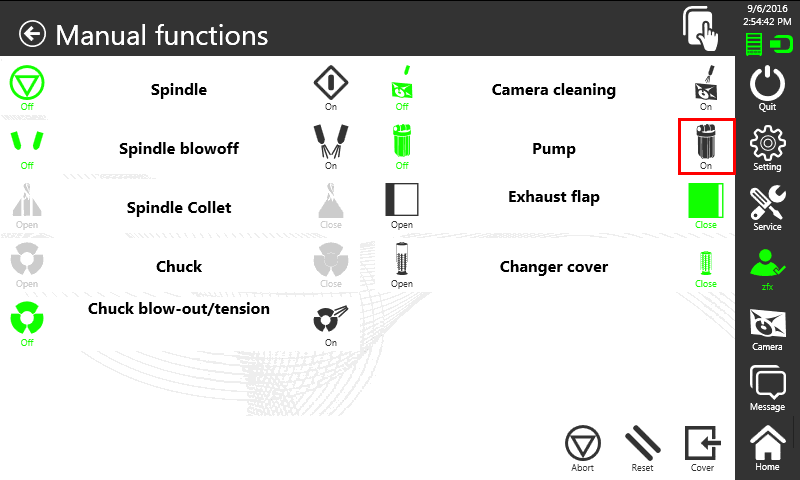

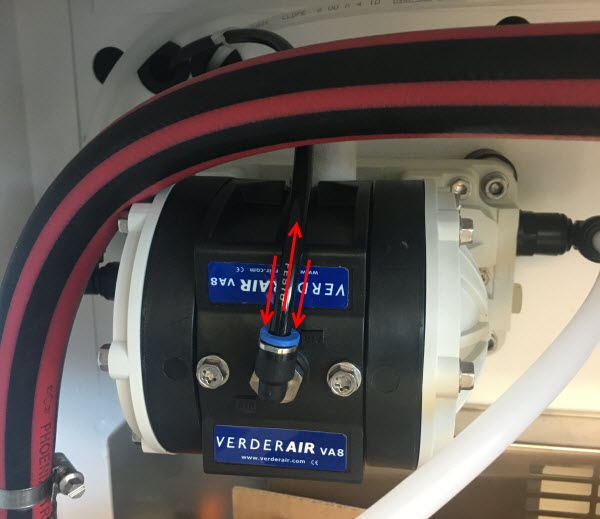

6) If the oil pump is not working, disconnect the tube of the compressed air supply from the oil pump, then switch on the pump.

Pay attention to the escaping compressed air!! By switching off the oil pump in the tab "Manual funcions", the air will also stop.

The tube can be pulled out while the blue ring is pressed down. To connect it again, just push the tube back in.

7) If compressed air is escaping, check if the sound absorber of the oil pump is soaked with oil.

This can be recognized if the sound absorber is yellow from the cutting oil, like below in the right picture.

You can also try to unscrew the sound absorber and start the pump again. If it is now working, the sound absorber must be changed.

8) If no compressed air is escaping, please contact the ZFX Service & Support Team.